People searching for “how to make a glory hole” are usually looking for real, practical information — not jokes, not theory, and not vague ideas. This guide explains the common DIY methods people actually use, what works, what fails, and what most people end up doing instead. If you prefer ready made stuff, check out our portable gloryhole options here.

Common DIY Glory Hole Methods People Use

When people talk about DIY glory holes, they’re usually not talking about cutting holes in walls. Most real-world setups are fabric-based, because fabric is portable, easy to work with, and doesn’t permanently damage anything.

There are three setups people keep coming back to.

Standalone Fabric Structures

This is the most straightforward DIY approach.

People use a simple freestanding structure — usually a lightweight frame — and attach fabric to it. The fabric is stretched or clipped across the frame, with an opening reinforced in the middle.

Why people go this route:

- it doesn’t rely on doors or walls

- it can be set up almost anywhere

- it breaks down for storage

The downside is stability. If the frame isn’t solid or the fabric isn’t tensioned well, things can shift, sag, or feel flimsy once there’s movement involved.

Doorway Mounts Using Tension Rods

This is probably the most common “clever” DIY solution.

People use pressure-mounted tension rods inside a doorway and hang fabric between them. The door frame becomes the structure, and the rods hold everything in place without drilling or screws.

Why this setup is popular:

- fast to set up

- no permanent damage

- feels stable when the doorway is solid

Door frames vary, tension rods can slip, and you’re locked into the size and position of the doorway. It works, but it isn’t very flexible.

We built a version with adjustable tension rods and no-slip pads to solve these issues. You can check it out here.

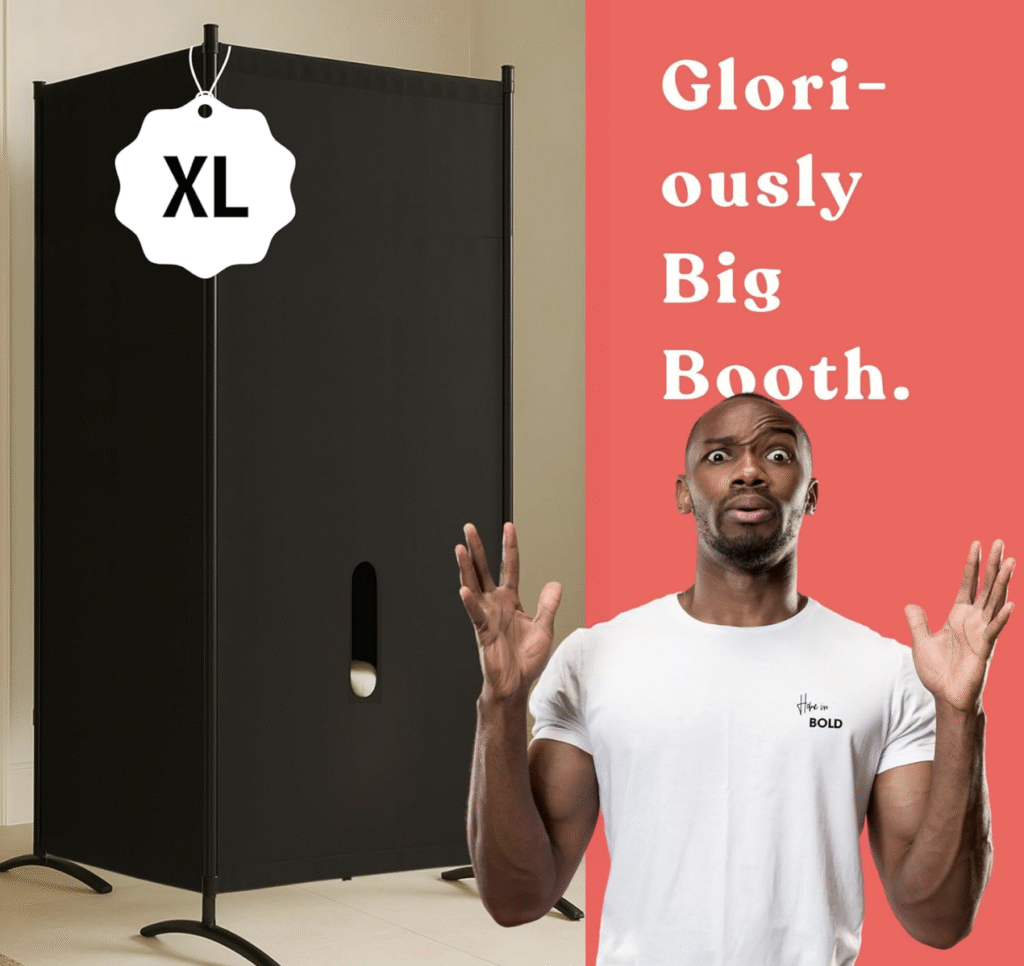

Booth-Style Setups

Booth-style setups are the most involved DIY option.

These work like a changing room or dressing booth, where the entire structure is enclosed. Fabric panels surround a frame on multiple sides, creating separation and maximum anonymity.

Why people choose booth setups:

- privacy is much higher

- the structure doesn’t rely on walls or doors

- everything feels more controlled and intentional

The tradeoff is portability. Booths are bulkier, heavier, and harder to carry or store. They’re the strongest portable option, but also the least convenient to move around.

After trying these setups, most people end up switching to something purpose-built. Some recommended portable glory hole versions can be found here.

Wooden Panel Setups

Some people prefer a more rigid DIY option and go with a removable wooden panel instead of fabric.

This usually involves cutting a hole into a plywood or MDF panel and positioning it inside a doorway, frame, or temporary support structure. The panel provides a firm surface and doesn’t flex like fabric.

Why people choose wooden panels:

- more rigid and stable

- the opening holds its shape

- feels more “solid” than fabric

The tradeoffs are weight and handling. Wooden panels are heavier, harder to store, and easier to damage floors or door frames if not padded properly. Edges also need to be finished carefully to avoid discomfort or injury.

What Usually Goes Wrong With DIY Glory Holes

Most DIY glory hole setups fail for boring, practical reasons. And not because the idea is bad, but because the details get underestimated.

These are the problems people run into over and over again.

Stability Issues

The biggest issue is movement.

Fabric setups can sag or shift.

Tension rods can slip.

Frames that seemed solid at first start wobbling once there’s real pressure or motion.

Even small movement breaks the experience and forces constant adjustment, which gets old fast.

Poor Hole Placement

This is one of the most common mistakes.

Once a hole is cut, its position and size are locked in. If the height is off or the opening is too small, the entire setup quickly becomes awkward or uncomfortable.

A lot of DIY builds fail here because people underestimate how much height variation and movement matter. What feels fine standing still often doesn’t work once things actually start moving.

That’s why many designs use a larger oval opening instead of a small round cutout. An oval opening allows more vertical flexibility and works across a wider range of heights and positions. In our own designs, a 9 × 2 inch opening is used specifically to accommodate that variation without constant adjustment. This is definietely important for our door mount models, because doors have different heights, so the curtain has some margin to go up or down, which means our hole definitely needs some vertical flexibility. See the image below.

If the setup is only meant for one specific person and one fixed position, a smaller round opening can work, but it requires careful measuring and leaves very little margin for error. If the height is misjudged, fixing it usually means rebuilding the panel or structure entirely.

Sharp Edges and Reinforcement Problems

Openings need reinforcement. Without it, fabric tears and wooden panels chip.

Fabric tears if it isn’t reinforced.

Wood chips if edges aren’t rounded and sealed.

Even small imperfections get noticeable over time.

That’s why finished designs reinforce the opening itself. In our models, the edges are stitched and reinforced, so the opening keeps its shape, doesn’t fray, and stays comfortable over repeated use. It’s one of those details that doesn’t seem important until you’ve dealt with the alternative.

Hygiene and Cleanup

For home DIY setups, people usually have the best luck with polyester microfiber. It’s easy to find, soft enough against the skin, doesn’t irritate easily, and cleans well with regular washing. It’s not perfect, but it’s about as good as you can get with off-the-shelf materials.

Where DIY setups struggle is consistency. Fabric stretches, frays, or degrades after repeated cleaning, especially around the opening. In our models, we use a custom fabric blend that’s soft to the touch, non-irritating, and designed to be cleaned repeatedly without breaking down. It’s built to stay comfortable and hygienic long term, rather than slowly getting worse with use.

Most people don’t think about cleanup until after the first few uses. By then, changing materials usually means rebuilding part of the setup.

Noise and Privacy Issues

Thin materials don’t block sound.

Loose frames creak.

Doorway setups transmit movement through the frame.

What felt discreet in theory often isn’t in practice, especially in shared living spaces.

Storage and Reuse Friction

Even when a DIY setup works, storing it is another issue.

Large frames take space and panels are awkward to move.

Fabric setups don’t always fold cleanly.

Anything that’s annoying to set up or put away eventually stops getting used.

Choosing One Setup for This Guide

For the purpose of this guide, we’re going to focus on one specific DIY approach: a portable standalone frame using a room divider.

There are a few reasons for that.

This setup is:

- relatively easy to put together

- fully portable

- doesn’t require a door or wall

- doesn’t rely on pressure rods or tension hardware

Most importantly, it lets people start from something that already exists instead of building a structure from scratch. A folding room divider gives you a frame, stability, and separation without committing to permanent changes.

That makes it one of the most approachable DIY options.

Starting From a Room Divider

Most room dividers are around 5 ft 9 in (175 cm) tall. That’s an important limitation to be aware of upfront.

For taller users, this means full anonymity isn’t guaranteed. Faces may be visible above the divider, and that’s simply a tradeoff of using an off-the-shelf divider instead of a custom-built frame. If complete coverage is critical, this approach may not be ideal but for many people, the convenience outweighs that drawback.

Another detail people overlook is clearance at the bottom.

The divider needs enough space underneath for feet to pass through comfortably. Some dividers sit flush to the floor, which makes positioning awkward or forces uncomfortable stances. Models with a small gap at the bottom tend to work much better in practice.

Accepting the Tradeoffs

This approach works because it keeps things simple, but it does come with limits.

You’re trading:

- maximum anonymity

- custom height

- total rigidity

for:

- portability

- ease of setup

- no permanent damage

- minimal extra hardware

For a lot of people, that’s a reasonable trade.

Everything that follows in this guide is written with this specific setup in mind, so the decisions around structure, fabric, and placement all build on that choice.

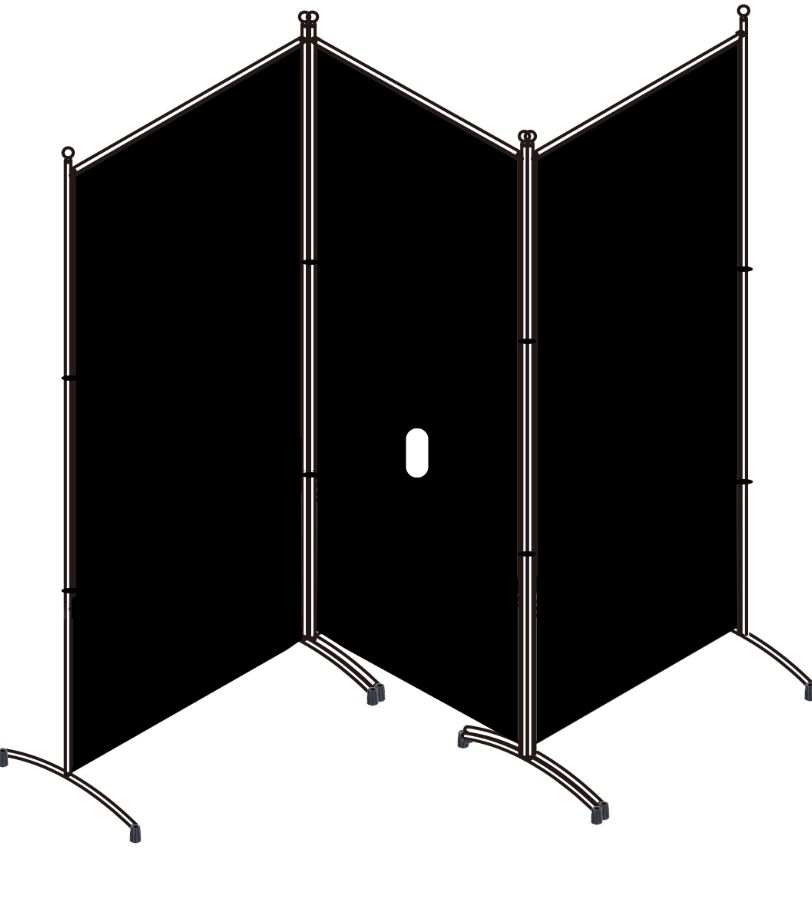

Step 1: Choosing the Right Room Divider

If you’re going to build a portable standalone glory hole setup, the first thing you actually need is the right room divider. This isn’t complicated, but picking one with the right characteristics makes the rest of the build way easier.

When you’re searching on Amazon or anywhere else, keep these practical things in mind:

Portability Matters

You want something that:

- folds up easily

- doesn’t take up a permanent corner of your living space

- isn’t heavy like furniture you’ll never move again

Look for dividers that collapse or fold flat. The whole point of this approach is temporary, mobile, customizable — so heavy, unwieldy panels defeat that purpose.

Multiple Panels = Flexibility

Dividers usually come with 3 or 4 panels. This is good.

More panels mean:

- better coverage

- more ways to position the opening

- more stability when wrapped around a frame

It also gives you more angles to work with when you’re deciding where the opening should be. A single flat panel box-steps around nothing; multiple panels let you create a curve or partial enclosure for a bit more privacy.

Easy to Modify

Not all dividers are equally easy to work with. Ideally, you want something where:

- fabric can be cut or attached easily

- panels are lightweight

- fixing or reinforcing doesn’t require power tools

Avoid metal lattice designs or glass/metal inserts unless you’re really comfortable with building — those are a headache to modify.

A cloth, wood, or pressboard panel divider is way easier to work with.

Clearance at the Bottom

As we mentioned earlier, the bottom of the divider needs a little clearance so feet can pass under without awkward positioning. If you find one where the panels sit flush to the floor, consider putting thin rubber feet or simple risers under the joints — but it’s mostly easier to just choose one that already has some gap.

Price Range Reality

Prices for room dividers on Amazon vary a lot:

- Budget models (lighter, thinner panels)

- Mid-range options (sturdier wood/cloth combo)

- Premium (decorative or heavier hardwood)

For a DIY build, you don’t need anything expensive. The goal isn’t a furniture showpiece — it’s structure + portability. A mid-range divider that balances stability and weight is usually the sweet spot.

Spend a bit more if you think you’ll reuse it again later for other purposes, but don’t overthink it.

Step 2: Cutting the Opening (Oval Placement)

The opening should be oval, not round, and the important part is that it spans a height range, rather than sitting at one fixed point.

For a general-use setup that works for people of different heights, the oval should start and end within a vertical range of about 29.5 inches to 39.5 inches from the ground.

That means:

- the bottom of the oval is around 29.5 inches

- the top of the oval is around 39.5 inches

This gives roughly 10 inches of vertical tolerance, which is what makes the setup usable for people of different heights and slightly different stances. That vertical forgiveness matters more than people expect.

Measuring From the Right Reference Point

If your divider has clearance underneath — for example, about 2 inches off the floor — you should measure from the bottom edge of the fabric, not from the ground.

In that case:

- the bottom of the oval should start at roughly 27.5 inches from the bottom of the fabric

- the oval then extends upward from there to cover the full usable range

Measuring from the wrong reference point is how openings end up too high or too low, even when the numbers look right on paper.

Size and Shape of the Oval

Width matters less than height, but it still matters.

A 3–4 inch wide opening is usually sufficient. Anything narrower becomes uncomfortable, and anything much wider starts creating alignment issues.

If someone claims they “don’t fit” through a properly sized opening in that range, they are — statistically speaking — lying.

The oval shape is important because it allows for:

- slight changes in stance

- small height differences

- natural movement

If the Setup Is for One Specific Person

If this setup is intended for one specific person only, the oval can be smaller and more precise.

In that case, people often:

- measure their own standing height

- note where their anatomy naturally lines up

- place the oval accordingly

Even then, it’s smart to keep the opening slightly oval rather than perfectly round, just to allow some margin for how you’re standing or shifting your weight.

Perfect precision sounds good in theory, but in practice it leaves no room for error.

Cut Once, Commit Once

Before cutting:

- stand the divider upright

- mark the full oval outline

- double-check both the bottom and top positions

Once the fabric is cut, fixing mistakes usually means replacing that panel. This is one of those steps where patience pays off.

Step 3: Reinforcing the Oval

Once the oval is cut, reinforcement is not optional. This is where most DIY setups fail over time.

Fabric without reinforcement will stretch, fray, or tear. Even if it looks fine on day one, repeated tension and movement will slowly deform the opening until it feels sloppy or uncomfortable.

Reinforcing the oval is what keeps the opening usable instead of turning it into a mess.

Why Reinforcement Matters

The opening takes all the stress.

Every bit of tension in the fabric pulls toward the cut edges. Without reinforcement:

- fabric slowly stretches downward

- the oval loses its shape

- edges become rough or uneven

Once that happens, fixing it usually means replacing the entire panel.

The Simplest Reinforcement That Works

For fabric setups, the most reliable DIY approach is stitching around the oval.

A tight stitch around the edge:

- prevents fraying

- helps the opening keep its shape

- spreads tension evenly instead of letting it pull in one direction

You don’t need fancy tools. A basic heavy-duty thread and a tight stitch pattern already make a huge difference.

If sewing isn’t an option, a fabric edging tape or sewn-on trim can work as a second-best solution, but stitching directly into the fabric holds up better long term.

Padding the Edge (Optional but Worth It)

Some people add a thin layer of padding around the oval before stitching it closed.

This can:

- soften the edge

- reduce pressure points

- make longer sessions more comfortable

It’s not required, but once people try it, they usually don’t go back.

How Finished Designs Handle This

The reason finished products hold up better is simple: the opening is reinforced by design.

In our models, the oval opening is stitched and reinforced, so it doesn’t stretch, fray, or lose its shape over time. It’s built to handle repeated use without degrading, which is hard to replicate consistently with DIY methods.

This is one of those details that doesn’t look important until you’ve dealt with an opening that slowly falls apart.

Final Check Before Moving On

After reinforcing:

- pull gently on the fabric around the oval

- make sure the shape holds

- check that there are no sharp edges or loose threads

If it feels solid now, it will likely stay solid later.

One important reality check before moving on.

Most room dividers top out around 5 ft 9 in, and even with good placement and reinforcement, that height cap doesn’t change. For taller users, this setup will almost always be too short to fully block the upper body. Faces and shoulders may still be visible, and there’s no clean way around that with an off-the-shelf divider.

Ours are designed to work comfortably for users up to 6 ft 3 in, with proper height, coverage, and reinforcement built in from the start. Some recommended versions can be found here on Amazon.

This is simply a limitation of the DIY approach.

Prefer a wooden set up instead? Here’s how to make that happen.

1. Quick-Start Checklist

| Item | Purpose | Pro Tip |

|---|---|---|

| Portable panel or door (¾-inch plywood or hollow-core interior door) | Light yet sturdy base | Aim for 26 × 40 inches—that slips into most car trunks. |

| Hole saw or jigsaw (2 ¾–4 ¾ inches) | Cuts a smooth, round opening | 3 ¾ inches is the Goldilocks diameter for most users. |

| Fine-grit sandpaper | Removes splinters | Wrap it around a bottle for a perfect curve. |

| Silicone flange or grommet | Cushions and seals the edge | Fish-tank-grade silicone is body-safe and inexpensive. |

| Fold-out legs or clamp brackets | Makes the panel freestanding anywhere | Tripod microphone stands bolt on neatly. |

| Hinges or coat hooks | Easy carry and storage | Two hooks let you hang the panel in a closet. |

| Wipe-clean finish (marine varnish or PVC wrap) | Sanitizes quickly | Matte black hides scuffs; whiteboard vinyl lets guests sign it. |

2. Step-by-Step Build

- Mark the Center Line

Prop the panel upright and mark 40 inches up from the floor—adjust if your expected guests differ in height. - Cut the Portal

- Drill a pilot hole just inside your circle.

- Run the hole saw or jigsaw slowly, letting the blade work.

- Test first with a cardboard template to avoid regrets.

- Smooth and Soften

- Sand every edge until it feels like glass.

- Seat the silicone grommet with neutral-cure silicone and let it cure for 24 hours.

- Add Legs and Locks

- Screw on fold-out table legs or bolt two adjustable mic stands to the rear corners.

- For a doorway mount, install swing-away hinges so the panel folds flat when not in use.

- Finish for the Road

- Apply two coats of marine varnish (or wrap in adhesive PVC sheet) for a wipe-clean surface.

- Drill a small finger-pull near the top for easier carrying.

- Optional Upgrades

- Clip-on blackout curtain for anonymity.

- Battery LED strip for mood lighting.

- QR-code sticker linking to house rules—tech-savvy consent.

3. Hygiene and Consent Essentials

- Surface Prep: Wipe down with 70 percent isopropyl or antiviral spray before and after each session.

- Barrier Protection: Condoms, dental dams, nitrile gloves—mandatory for every participant.

- Safewords and Signals: Agree on a clear stop cue (knock pattern or verbal word) before anyone starts.

- After-Care: Warm towels, gentle soap, plenty of water, and reassurance.

5. Maintenance

- Inspect weekly for cracks, loose screws, or splintering.

- Reseat silicone if it starts peeling—hygiene first.

- Store the panel upright in a dry place; moisture ruins plywood and passion alike.

6. Prefer to Buy Ready-Made?

- Flat-pack gloryhole panels cost roughly $40–$220 online. (At least, the ones we recommend)

- Look for sealed edges, quick-release legs, and body-safe materials (silicone, ABS).

- Check reviews for build quality and discreet shipping.

Final Word

A DIY Gloryhole To Go is a weekend DIY that delivers years of discreet adventure—provided you keep it clean, consensual, and within the law. Build responsibly, maintain diligently, and let the good times roll.

Final Thoughts on DIY Glory Hole Projects

Building a DIY glory hole can be an educational project, but it comes with real trade-offs.

Understanding those trade-offs helps people decide whether experimenting is worth it or whether a ready-made solution better fits their lifestyle.

Knowing both paths allows for deliberate choice rather than trial and error.

Frequently Asked Questions About how to make a gloryhole

Can you learn how to make a gloryhole at home

Yes, but it requires careful planning, proper materials, and attention to safety and discretion.

What is the biggest risk with a DIY glory hole

Permanent damage, instability, and safety issues are the most common risks.

Are DIY glory holes renter friendly

Most are not, especially those involving wall or door modifications.

Why do people switch from DIY to portable options

Portability, discretion, and ease of storage are the main reasons.

Is a portable glory hole safer than DIY

Purpose-built portable options are generally safer because they are designed and tested for the specific use.

Can a glory hole setup be stored discreetly

Portable solutions a